Use

Developing useful educational toys

SECURITY

Making safe educational toys

Life cycle

Recycled and recyclable toys

Impact

Limiting the impact of our toys

THE STEPS IN MAKING A SIMPLE TOY.

#1

CO-DESIGN

For us, there is nothing more important than making useful toys that appeal to parents and children (of course), while having the least possible impact.

To do this, we set up co-design workshops during which we imagine, with parents and early childhood specialists, the future toys that we will develop.

Co-design is at the heart of all our projects. This is an important process of consultation to ensure we create useful toys .

This is the first phase of development for a Le Jouet Simple toy. It's important to be transparent and informative, especially with the people involved in designing our toys. They willingly share their suggestions, advice, and feedback. This feedback allows us to identify areas for attention, list relevant observations, and choose the final design to move forward with.

#2

DESIGN STUDIO

Toys to play with.

It seems obvious, but it's always worth remembering. Use is what guides the design of our toys: beautiful, responsible, fun, and practical. Quite simply.

To imagine Le Jouet Simple toys and bring our ideas to life through sketches and 3D, we work with independent designers specializing in childcare products.

Our partner studio is based in the Pays de la Loire region. Working for many years in the early childhood field, they are specialists who place children at the heart of their responsible design approach. They take into account the diverse needs of young children's social and psychomotor development.

Beyond the educational and awakening functions, toys must meet industrial constraints which are taken into account from the design phase.

Thus, French manufacturing and eco-design are the very foundation of the first designs. It is necessary to be able to integrate and respond to pre-established challenges: manufacturing single-material toys, without glue, metal, screws, or stickers. A major challenge that requires a perfect understanding of materials, manufacturing processes, and ultimately technical feasibility.

Design is the key to making a toy.

Following the drawings, comes the pre-industrialization stage, carried out in collaboration with our design office.

#3

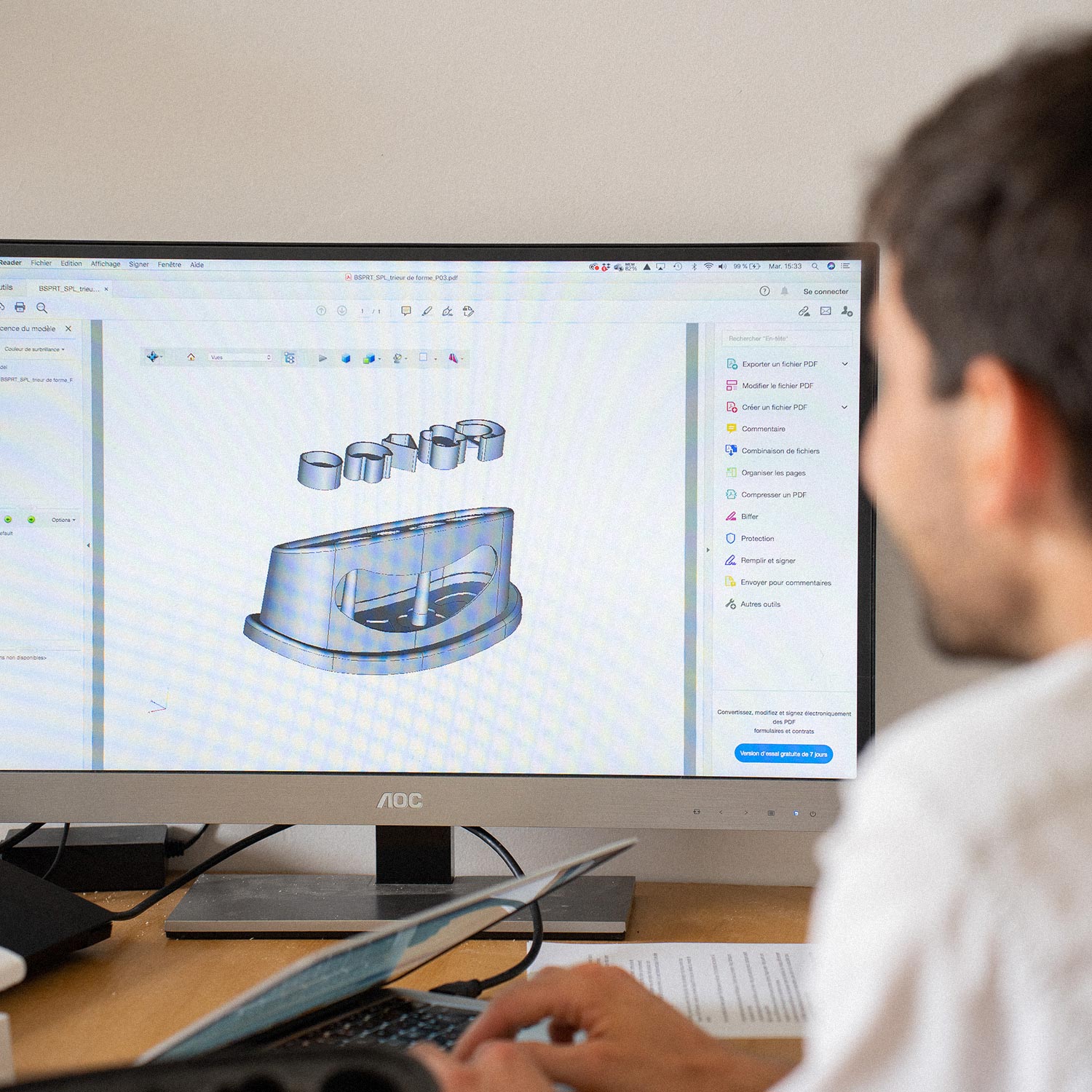

DESIGN OFFICE

Test, study, repeat, and improve. This is the daily routine of this pre-industrialization phase.

Creating several 3D-printed prototypes allows us to ensure the feasibility of our ideas and to ensure that all manufacturing constraints are taken into account. We also use these prototypes to test the toys with children to ensure they are comfortable handling and understandable.

To support us in this step, we are working with a design office located in Maine et Loire.

The team is comprised of engineers and technicians with specific expertise. Specializing in childcare products, among other things, the design office allows for the manufacturing of injection molds based on drawings.

It is during this stage that we manufacture the injection molds used to mold the toy parts. For the same toy, we sometimes need 4 to 6 different molds depending on the number of parts it contains.

Our molds are unique in that they are custom-made to fit recycled materials—a rare feat in the toy market.

Once the prototypes have been validated, the first molds are made and we can start manufacturing the toys by plastic injection.

#4

THE MANUFACTURING PLANT

Most toys are made from various types of plastics and materials (electronics, screws, stickers, etc.). This makes them difficult to recycle and, most of the time, very weak.

At Jouet Simple, we impose one constraint: manufacturing single-material toys without glue, screws, or stickers, and using a single type of plastic. This makes the entire process more complex than conventional toy manufacturing. Yet, it's the key to designing eco-responsible and 100% recyclable toys.

Our toys are manufactured in a factory specializing in plastic injection molding. Located in Ain (01) near Oyonnax. A company founded in 1960 that manufactures our toys as well as other plastic parts for everyday products, with the expertise of around thirty employees.

Each part is molded separately on large plastic injection presses weighing several tons (photo opposite). We manufacture parts in batches of several thousand to ensure we have the necessary stock to meet demand.

The parts are then sent to our assembly workshop.

#5

THE ASSEMBLY

Whenever possible, we apply our virtuous loop principle to all stages of toy design.

Some of our products are assembled in a suitable facility to support the activities of people with disabilities.

Located in the Auvergne Rhône-Alpes region, our partner is a 36-person adapted company that has been actively involved in reintegration through work since 1993.

It's in this workshop that the toys are assembled, boxed, and then delivered to the stores. A veritable Santa's workshop!

For smaller orders, we have another workshop-warehouse in the Mayenne department. This allows us to both store all of our toy spare parts and respond quickly to all requests. This flexibility and responsiveness are essential in the toy market.

The assembled toys are boxed in custom-made packaging.

#6

THE PACKAGING

Packaging has a significant impact on the environment but is also necessary for the proper understanding and protection of products.

It is essential to give them as much importance as toys.

We design custom-made cardboard boxes for each of our products. Minimalist and printed with a few different colors, these boxes are made in France. They protect toys while providing information about the product. There is no single-use plastic in our packaging; it is 100% cardboard.

To design them, we work with a cardboard manufacturer with several industrial sites across the country and extensive expertise. Our boxes are manufactured in Normandy and the Île-de-France region.

TOYS LABELED ORIGIN FRANCE GUARANTEED

All these manufacturing stages are certified by an independent organization, allowing us to have toys labeled Origine France Garantie. This is a trusted label issued following an audit. This gives you the certainty that our toys are truly 100% Made in France. This means more than fifty different people work alongside us on the different stages of the toy manufacturing cycle.