WHAT IS A MONO-MATERIAL TOY?

Monomaterial means we use only one material. Nothing else. No glue, no screws, no paint, no stickers. It's all about the design and the concept of how the pieces fit together. This is our recipe for creating toys that are 100% recyclable, durable, and washable.

controlled

A raw material that complies with current safety standards

safe

The material is analyzed and certified by an independent laboratory

RECYCLED

A material made from scraps from the manufacturing of everyday products

RECYCLED MATERIAL

HDPE (High Density Polyethylene) is a commonly recycled type of plastic.

Used in the manufacture of many everyday products, such as shower gel bottles, milk bottles, etc., this type of plastic is fully integrated into the recycling sector on a European scale.

We recognize it thanks to its marking bearing the number 2.

Once collected, it is sent to a sorting plant, where it is crushed, cleaned, and then prepared for further use.

We recycle and transform manufacturing scraps from everyday products made from HDPE into toys.

Today, too many toys are made from non-renewable fossil resources. Yet, we believe that it is possible to act differently to preserve our shared playground: the planet.

This is why we have chosen responsible production, based on the principles of eco-design and the circular economy.

The circular economy is at the heart of our commitment.

FROM RECYCLING TO TOYS

#1

COLLECTION & SORTING

Collection and sorting are the first steps in recycling and are carried out by our partner, a recycling expert based in Normandy.

The plastic we process always comes from the same source to ensure traceability. Depending on the time, it comes from offcuts from the manufacturing of flasks, bottles, or other everyday objects.

HDPE is one plastic among others and we do not mix it with other types of plastic in order to always be able to meet our industrial manufacturing constraints and the quality that we impose on our products.

Other types of plastic include PET (Polyethylene Terephthalate), PVC (Polyvinyl Chloride), ABS, PP (Polypropylene), etc.

#2

CLEANING & GRINDING

Once sorted and collected, the plastic will enter the crushing and cleaning stage.

A long process which consists of grinding the plastic into small, more or less homogeneous pieces so that it can then be processed industrially.

#3

COMPOUNDING

Compounding occurs after plastic grinding. This is the step that transforms the ground plastic so that it can be reused industrially. Thus, the small pieces of plastic that were initially ground are transformed into small, uniform beads.

We source it with white or translucent plastic which can then be colored as we wish with our palette of 4 colors typical of our toys.

#4

QUALITY CONTROL

Before using the pellets for production, a quality control is carried out to verify the conformity of the HDPE.

Rigorous testing is conducted by independent laboratories to ensure that the plastic meets the safety, durability and non-toxicity standards essential for toy manufacturing.

Each batch of recycled plastic used meets all current EN71, REACH, ASTM and CE standards to ensure it is free from endocrine disruptors and controversial substances (no BPA, phthalates or PVC).

#5

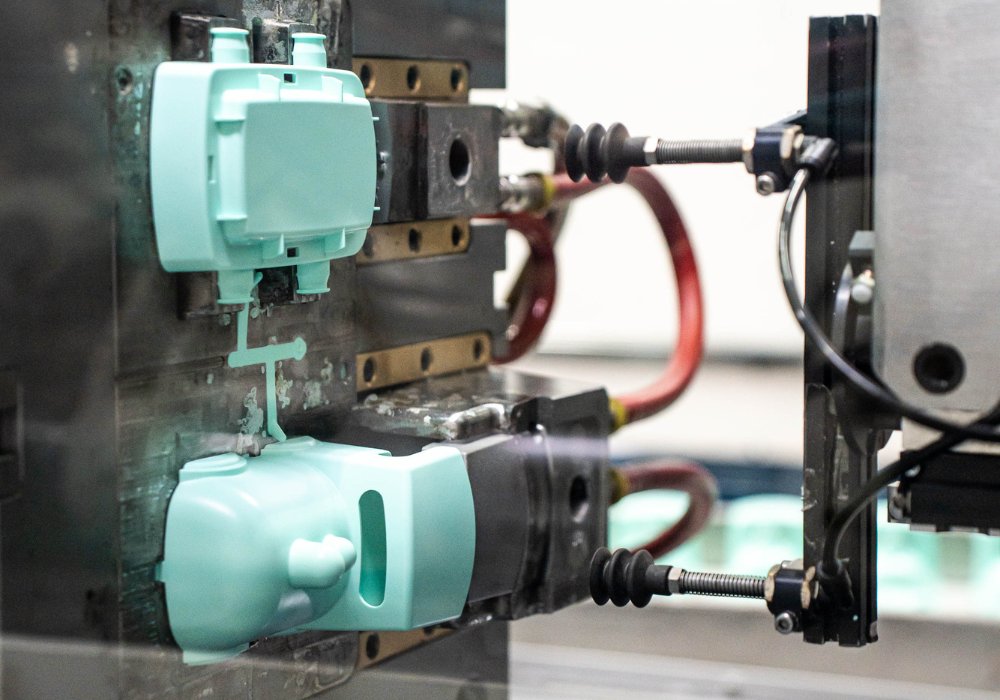

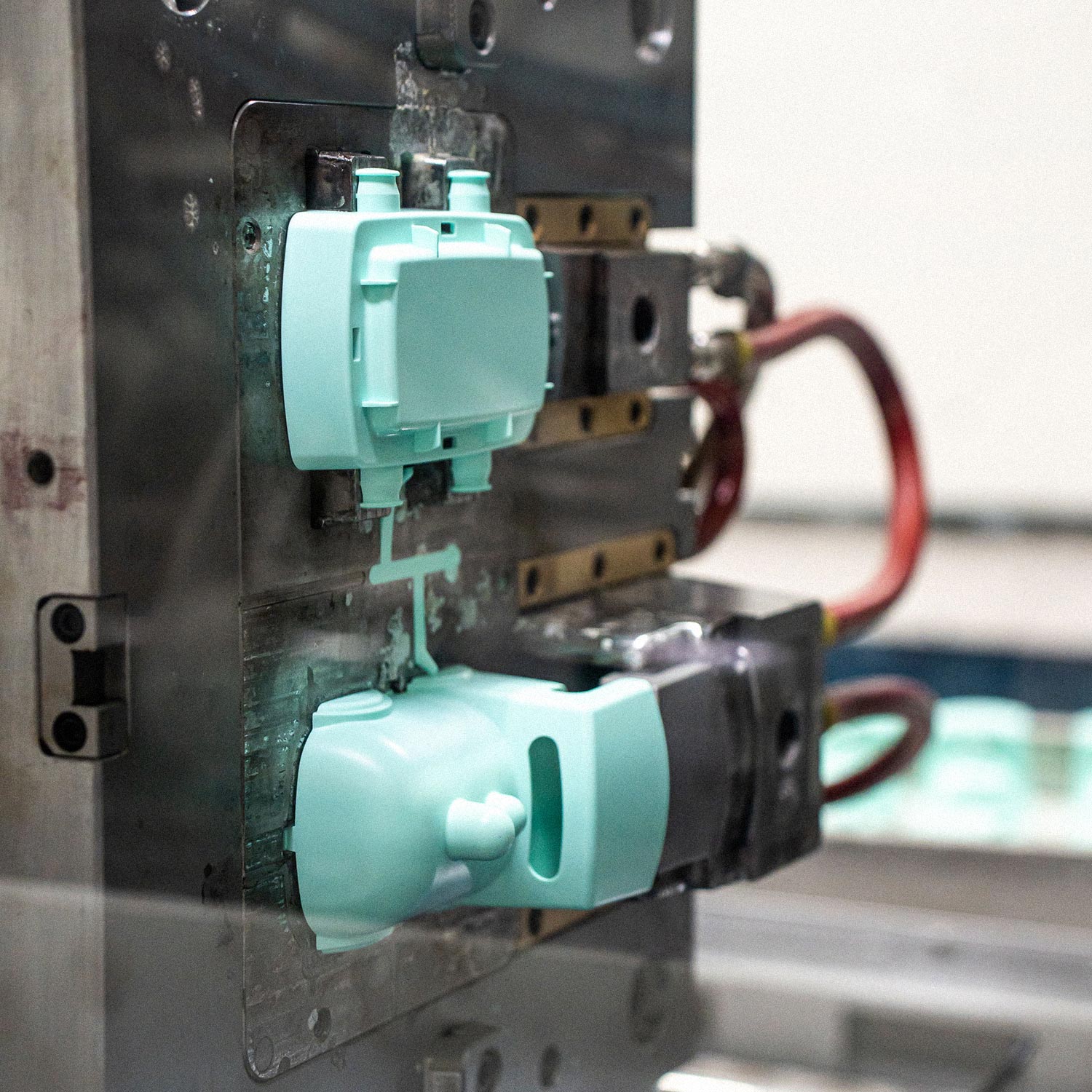

CASTING & MANUFACTURING

Once the raw material has been validated, we launch production.

The plastic will then be heated, melted (like chewing gum) and then mixed with our coloring before being injected into the molds.

By adding the colorant at this stage, it ensures that there is no deterioration of the color and that no additives are used; this is what is called "colored in the mass."

Our injection molds (photo opposite) are specially manufactured to transform recycled material, which is a particularity in the toy industry today.

Once injected into the molds, the plastic takes the shape of the different parts of the toy.

#6

ASSEMBLY & FINISHING

Once molded and cooled, the toy parts are sent to the assembly workshop.

Each piece is designed to fit together to ensure the production of single-material toys. Thus, it's all in the design since we don't use metal parts or glue to assemble our toys. This is the only way to ensure we produce toys that are 100% recyclable, waterproof, and dishwasher-safe.

Once assembled, one copy of each toy is sent to the laboratory for final inspection to ensure its strength, functionality, and compliance with safety standards.

#7

USE

It is through this process of recycling and transformation that Simple toys are born.

Once boxed, the toys are ready to be distributed and end up in the hands of children who will invent many stories!

They are 100% recyclable, durable and safe.

Designed to be used sustainably while reducing environmental impact, thanks to the circular economy.

100% CONTROLLED

Rigorous analyses are conducted by independent laboratories to ensure that the plastic meets the safety, durability, and non-toxicity standards essential for toy manufacturing. The toys meet all current safety standards, such as EN71 and CE, and are therefore guaranteed to be free of endocrine disruptors (no BPA, phthalates, or PVC).